| |

| ≡ Membrane desicator

|

>>>>Present

page:Membrane desicator |

|

|

Vertical

membrane desicator : |

|

● Operation

principle : ● Operation

principle :

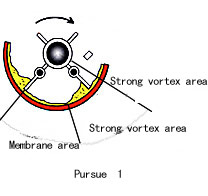

Membrane desicator, mainly by blow mechanical

force of slice produce one strong a layer of liquid

film of turbulance it (Fig. 1) .

This dry technology is setting up on WFE foundation

of shaving the membrane evaporimeter , with engaged

in the experience of dry technology for a long

timing; WFD desicator can work in heating temperature

from- 20-1100 degrees Centigrade, working pressure

0. 01-30bar, the range from second to hour in

the time of staying .

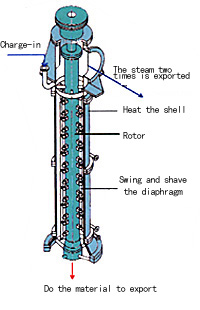

Fig. 2 is the vertical membrane desicator ,

it shaves one slice of rotors etc. to make up

from what has been taken outside to heat the vertical

round barrel which inserts set , swing from side

to side. This is it blow slice from insert sets

of wet supplies that top enter distribute to heat

surface to swing, this thickness of layer of liquid

is decided by and shaved one and interval between

the barrels, is swinging forming a very strong

vortex above of the blade, turbulance this strengthen

liquid film heat transfer on heating surface,

among this course, this light to give copy evaporation

form two steam been the external condenser successively,

powder that freedom flows left the desicator through

a proper systematic spacer assembly 。

For prevent material liquid from heat surface

form dirt , this is it blow slices of high guard

station become and heat Taxi interval 1mm to swing,

liquid film layer can smaller than 1mm thickness

in this way, but to heat surface have clean function

since 。

Usually, the dry course of the membrane desicator

can divide into three areas : Preheating area

, condensing area , dry district ;

The preheating area, the supplies reach the

boiling point begin to evaporate, the solid take

shape tentatively 。

Condensing area: The solid density increases,

tend to a stage of forming the group , a lot of

products are swung and shaved one to crush during

this time 。

The dry district at the end, the moisture (low

boiling thing ) volatilizes and finishes with

the dry course ;

The length of each area depends on the speed

of charge-in of the products and includes wet

quantity to a great extent, charge-in speed increase

person who preheat and is it increase to condense,

final result dry to is it is it include wet composition

increase finally to lead to the fact to reduce

。

It is heated that there are saturation steam

, heat conduction oil , far red dispatch from

foreign news agency to heat the medium ;

● Characteristic

1、 Time is short, it can be guaranteed to evaporate

slowly under the vacuum condition that this is

dry that the supplies are heated 。

2、 Operation airtight continuous, so without

concentrate loss pollute 。

3、 This shaves the membrane device and prevents

supplies lumping or structure in heating the surface

。

4、 The concentrate is transported and entered

a simple evaporation pot, during a single cycle

, the initial one is concentrated and had nothing

to do, the dry products can be produced, in this

passway of smooth forms 。

5、 Initial solution concentrate output , this

mean minimum residue amount of limit and reduce

and dump overcoats until solid material 。

● Apply to :

1、 Dry dyestuffs and pigment growing , weed killer

, leaf and make the accomplishment of fungus yellowly

, to sour second ester of amino benzene ,etc.

;

2、 Retrieve solvents in the media of studying

in Conghua ;

3、 Deal with and dry life or industrial sewage

; |

|

|

|

|